For this project, as with numerous others, the initial step involved a 3D scan. The VW T5 van underwent a thorough process: all ply lining was removed, and the interior was meticulously cleaned to create an optimal scan environment. To address the glossy nature of the van’s paintwork, we applied additional talcum powder and dry shampoo, enhancing the scanner’s ability to capture surface details.

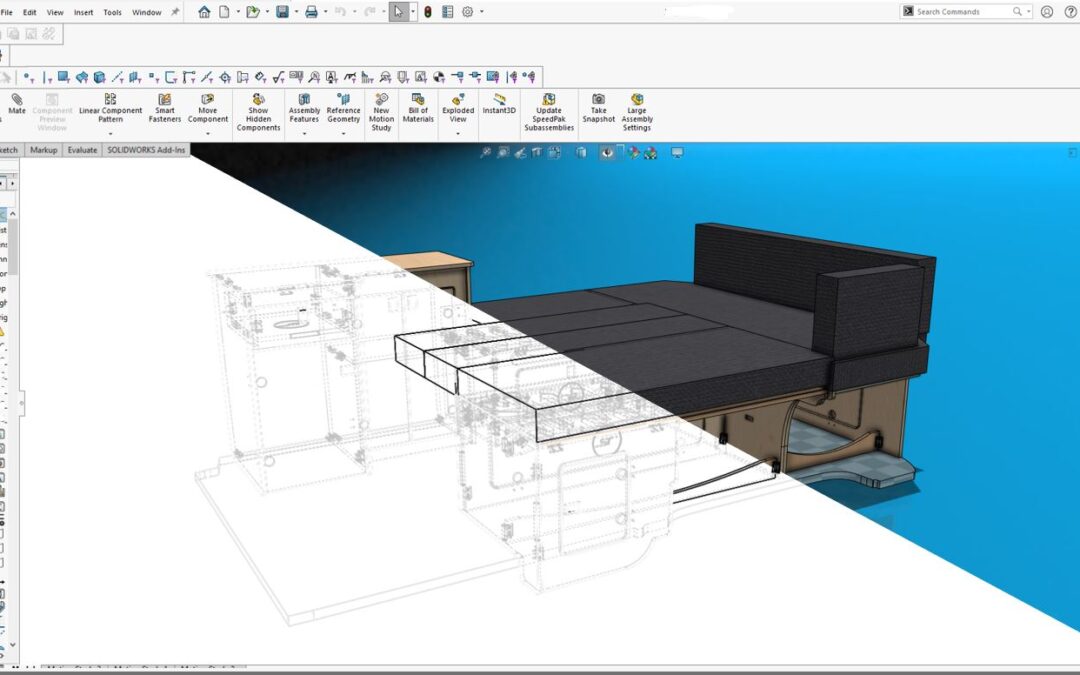

By integrating the 3D scan data with precise physical measurements, we strategically devised and designed the furniture layout using Solidworks 3D modeling software. This approach minimizes the need for extensive trial-and-error wood cutting, significantly expediting the timeline from the initial concept to the ultimate design.

Augmented reality played a crucial role in providing a clear understanding of the furniture’s size in relation to the van. In the realm of 3D models and CAD work, maintaining perspective can be challenging, and augmented reality serves as a valuable tool in aligning designs with real-world dimensions.

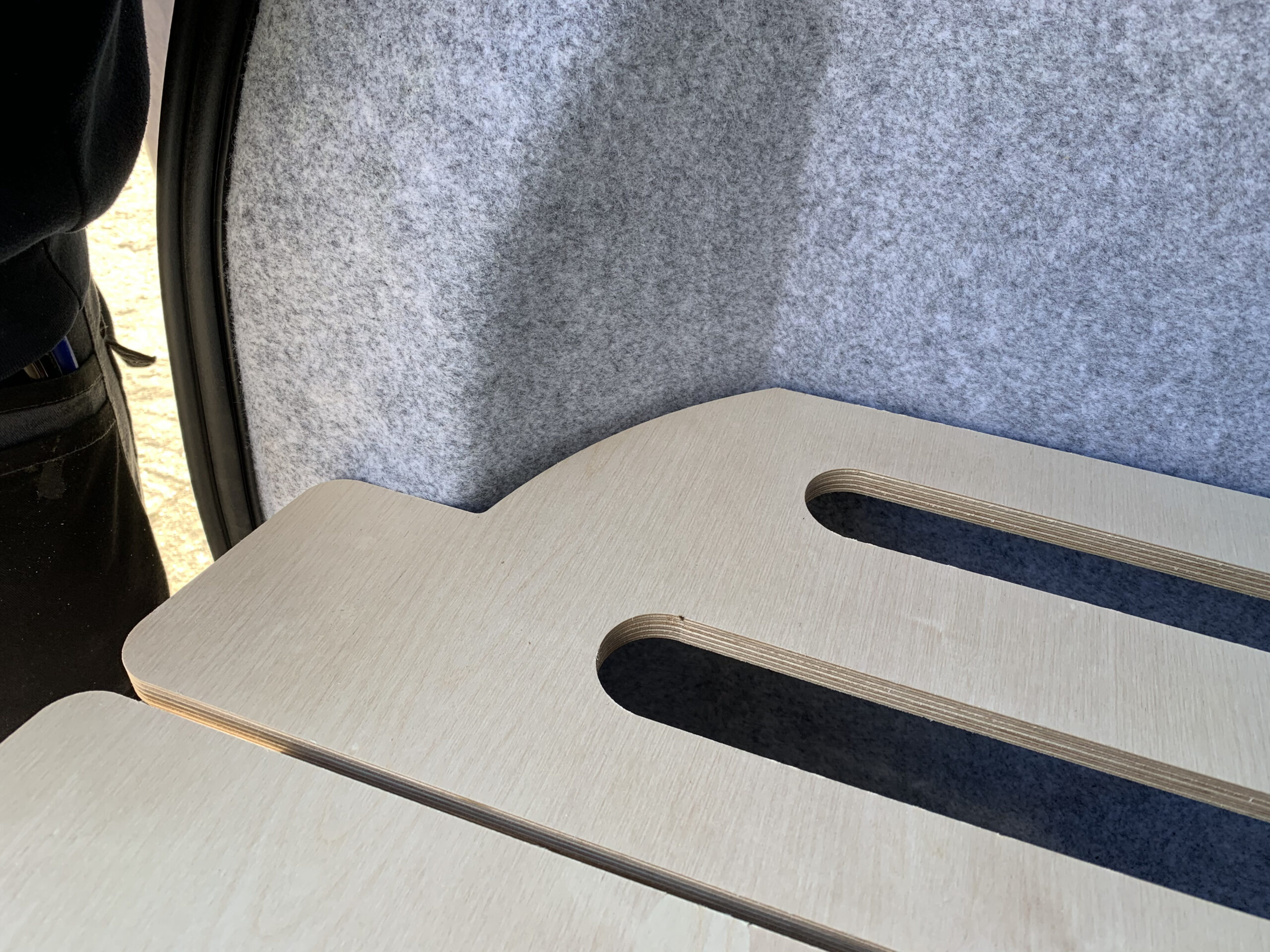

The use of 3D scan data allowed us to follow the internal shapes of the van accurately with minimal prototyping.

The end product is a well designed and thought out layout that the customer can repeat over and over again on their CNC machine.