When initially approached for Mechanical Design support on this project, memories of director Pete’s early driving days in the MK2 Golf Driver flooded back. Given our shared passion as devoted car enthusiasts—some may even call us “petrolheads”—this project instantly captured our curiosity. Without hesitation, we made the decision to dive into this exciting venture at TEH.

The initial step involved a visit to the customer’s workshop, providing us with the opportunity to inspect the vehicle firsthand and gain a comprehensive understanding of our role in the project.

ROAD TRIP!!

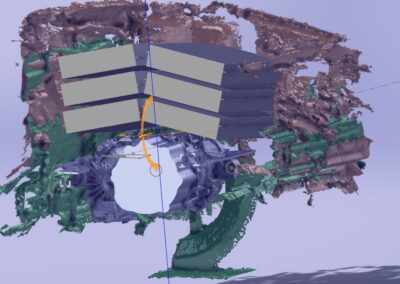

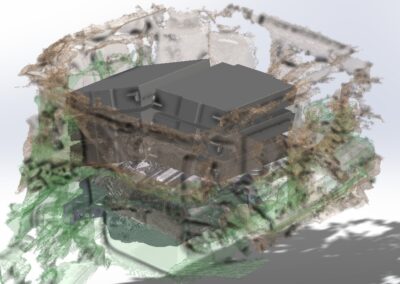

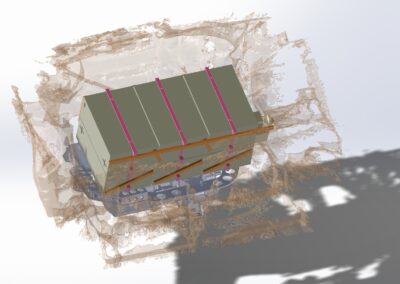

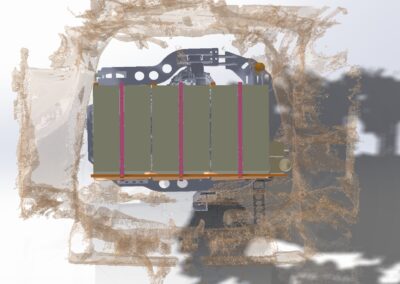

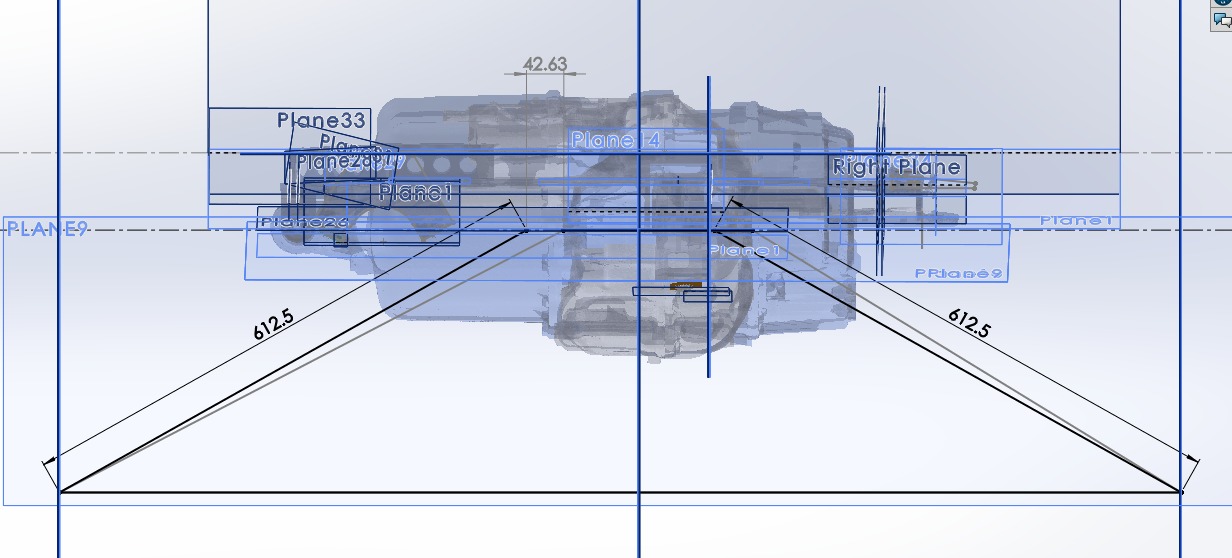

After initial inspection the customer was advised that the project was viable and we set about taking measurements and 3D scans of as many data points as possible.

Note: The vehicle had already had modifications prior to our involvement. We would not advise modifications to the monocoque of the vehicle in any shape or form.

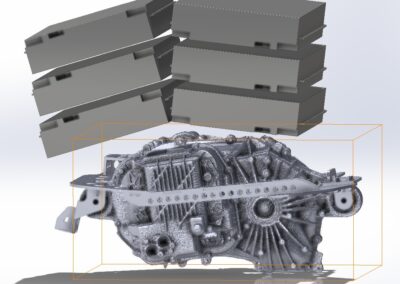

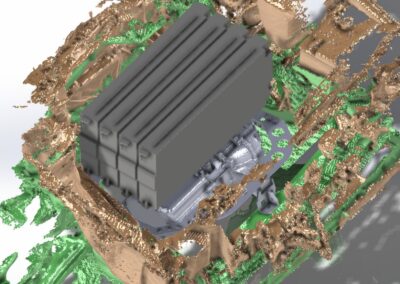

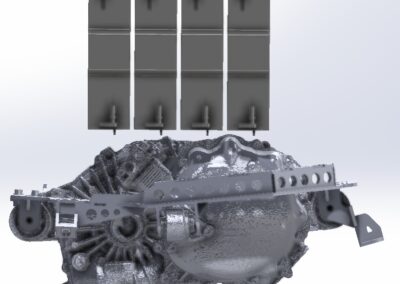

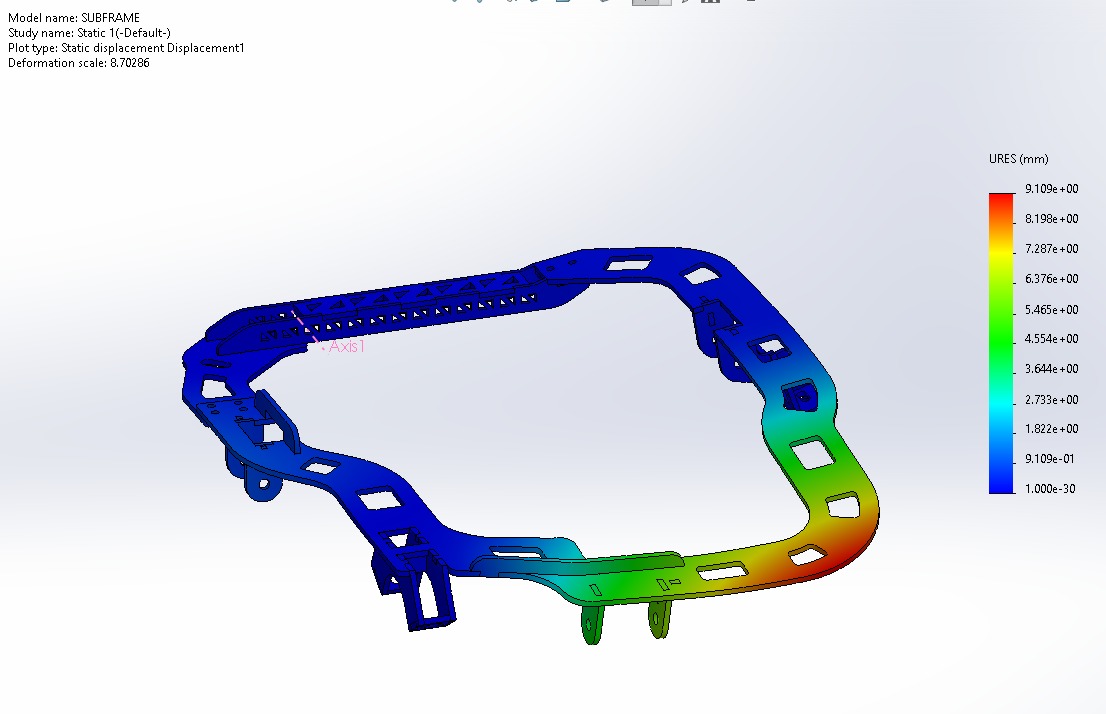

We took the scan data and transformed it into point data compatible with Solidworks. Using this, we developed an initial concept and conducted several Finite Element Analysis (FEA) studies. Our focus was on ensuring the design’s strength in key areas while keeping the vehicle’s weight to a minimum. Crucially, we strategically positioned the motor/differential to achieve equal-length driveshafts, a vital consideration for minimizing torque steer when dealing with substantial torque on the front wheels.

SPECIAL MOMENT!!

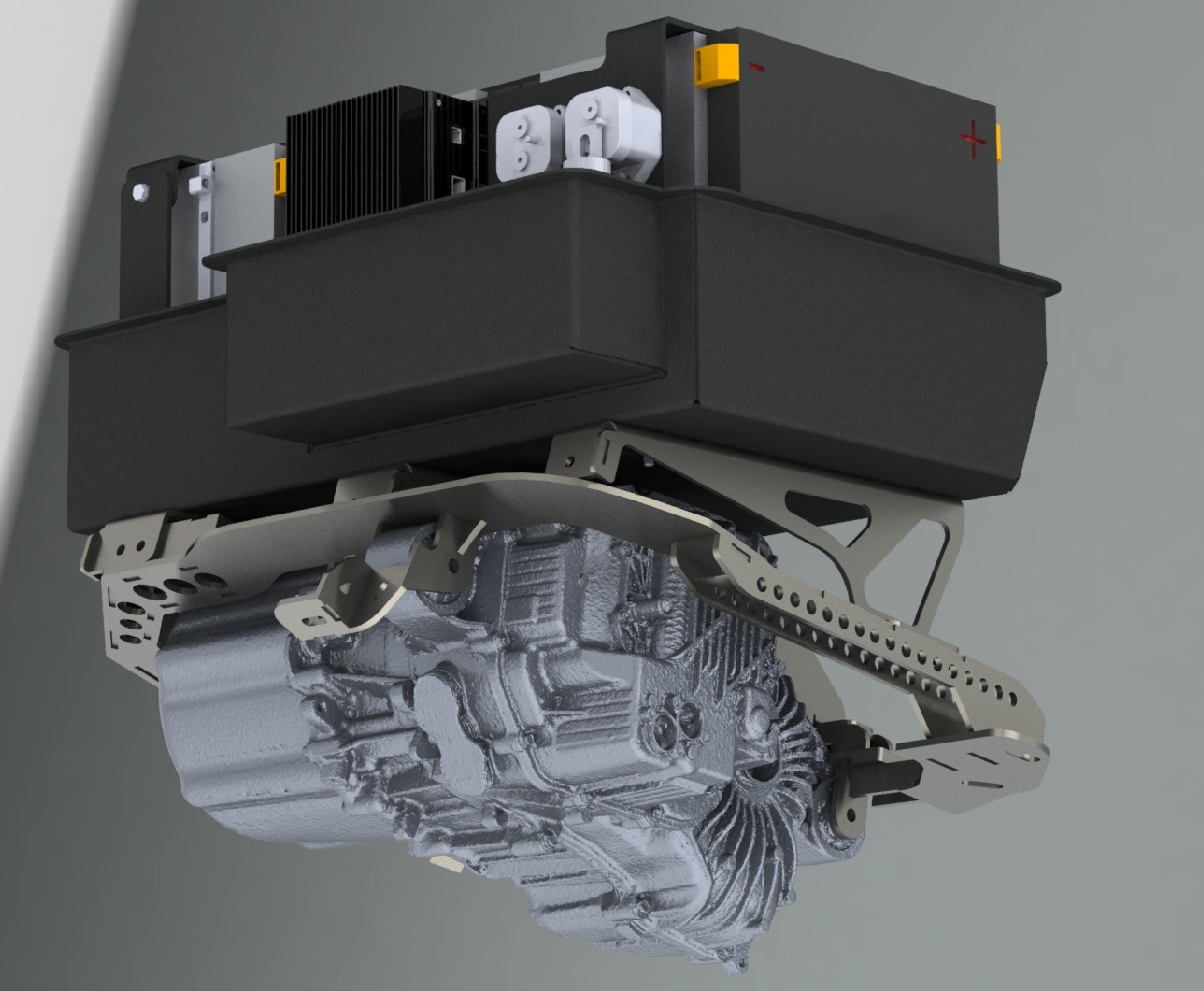

This being our first attempt at a project like this and the fact that the space envelope was extremely tight – the decision was made to create a full size steel prototype. Steel was laser cut and welded and we physically mounted the Tesla motor into the Golf engine bay for the first time!

Initially the customer specified Tesla batteries to be mounted above the Tesla motor (below the bonnet). To say it was tight is an understatement! Never the less we set about squeezing the batteries in using every mm we could find. Part way through the project the customer changed the choice of Battery to LG Chem modules – so as they say “Rinse and Repeat”!.

With the design finalised, it was time for the final build at the fabricators. The outcome is a discreet and neat installation, breathing new life into the MK2 Golf with a significant boost in power.